Process of elevator manufacturing includes several stages as follows:

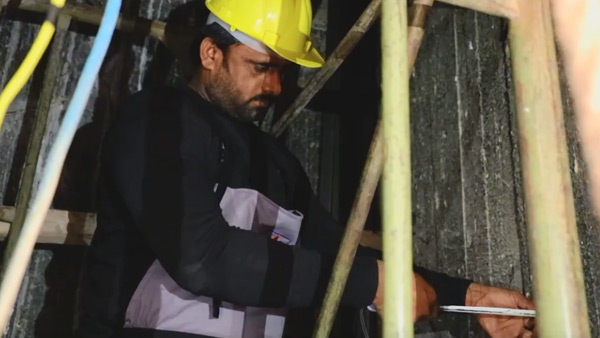

Measurement:

- 1. Measuring customer’s elevator shaft to accurately determine the dimensions of the elevator, taking into account the type of landing door, whether automatic or manual, as required by the customer, and ensure the possibility of installation on site.

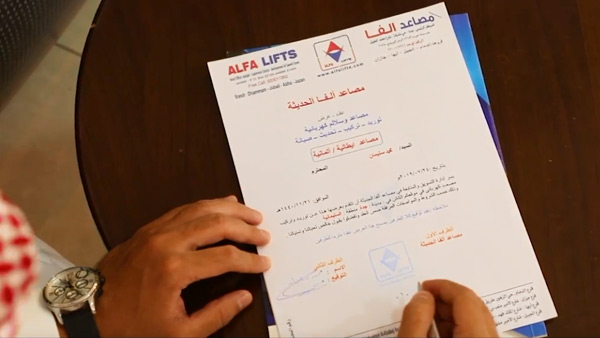

Signing Contract:

- 2. Preparing price offer based on the agreed requirements by the customer and then sign the contract.

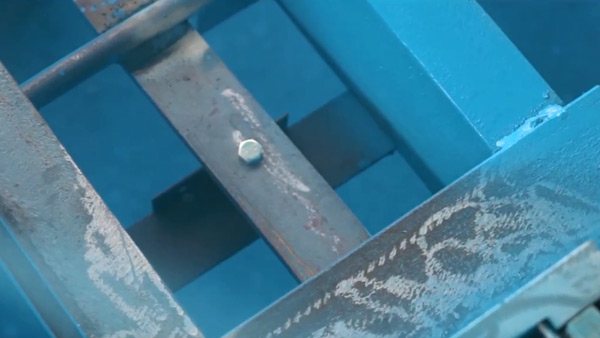

Manufacturing:

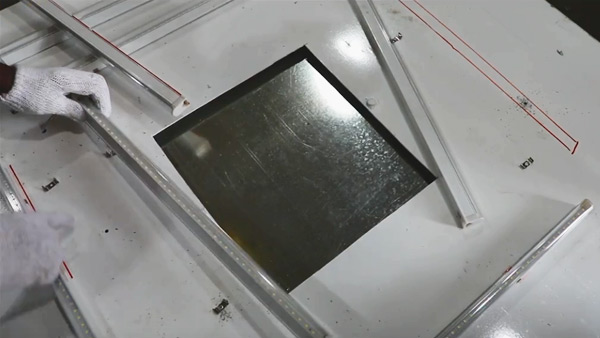

- 3. Manufacturing, cutting and welding parts of the metal structure of cabin (chassis) of the iron steel, and then coating it with a moisture-proof stainless-steel coating.

- 4. Manufacturing interior cabin walls from stainless steel or as per customer's choice of materials and engravings by cutting and covering entire cabin interior.

- 5. Manufacture of interior cabin roof of stainless steel or as per customer's choice of materials and engravings, and covering interior cab roof with installment of light fixtures and ventilation fans.

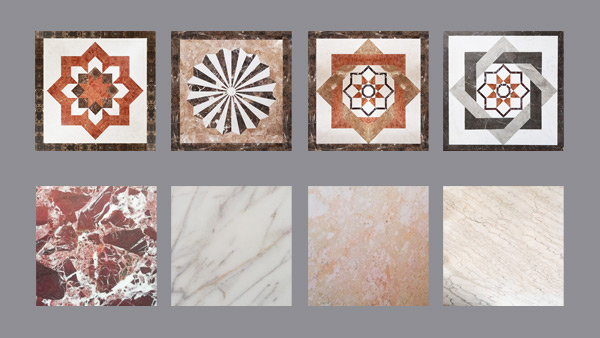

- 6. Manufacture interior cabin flooring made of marble or as per customer's choice

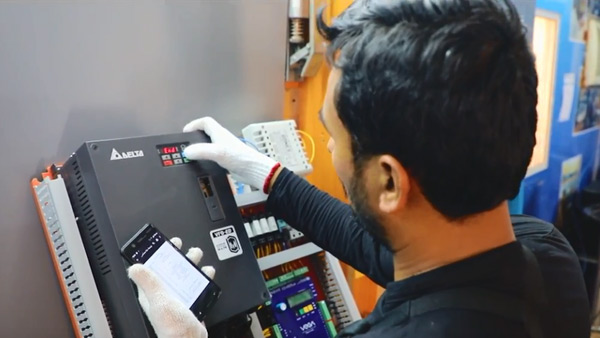

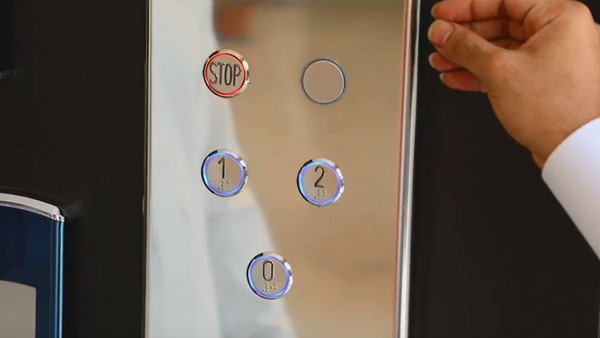

- 7. Manufacturing and assembling the control panel and practically testing it on elevator motor.

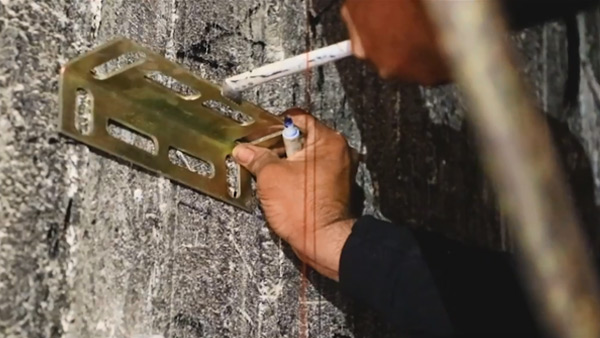

Installation:

- 8. Installing and accurately weighing elevator Guide Rails of iron steel.

- 9. Delivering all parts of the elevator to customer's installation site

- 10. Assembling elevator parts and then installing doors, machine, cabin, internal and external control buttons and control panel.

- 11.Finally, Running and pilot testing the elevator, and then deliver it to the customer.